Below is an overview of various benefits that can be acquired through a well-informed choice of welding technique. In many cases, the choice depends on a unique mix of requirements, involving factors such as the complexity of the welds, production volume, available budget, and the

overall goals of the manufacturing process. We are happy and able to help you make a reliable evaluation.

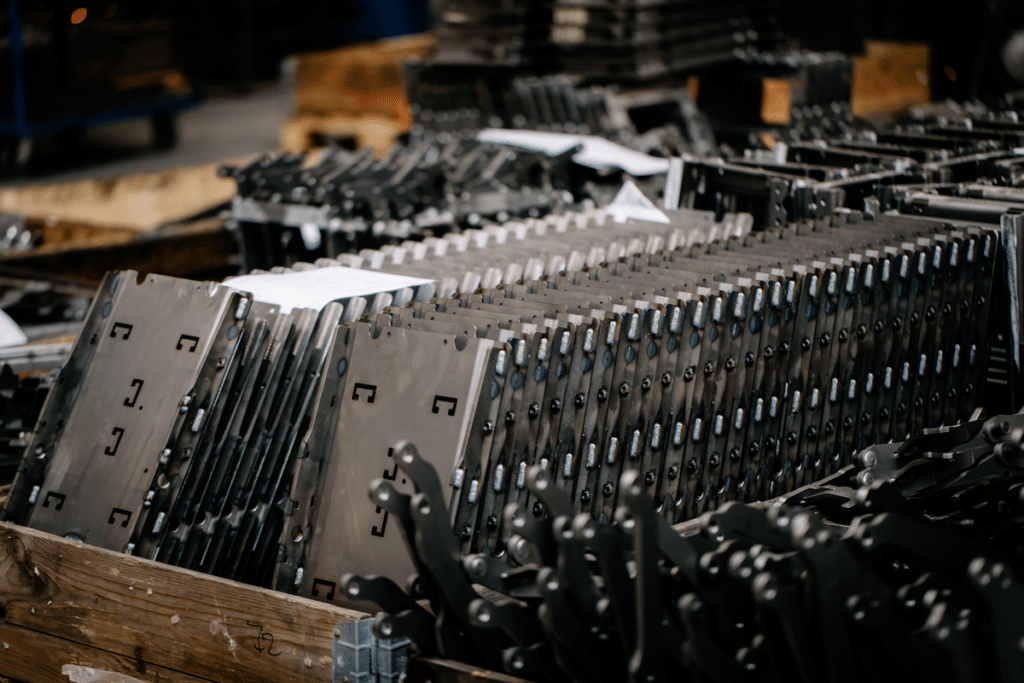

High productivity

Robotic welding is well-suited for high-volume production, as it can operate continuously without breaks, leading to increased efficiency and

productivity. Specifically, robotic MIG/MAG welding is known for its high deposition

rates, resulting in faster welding speeds.

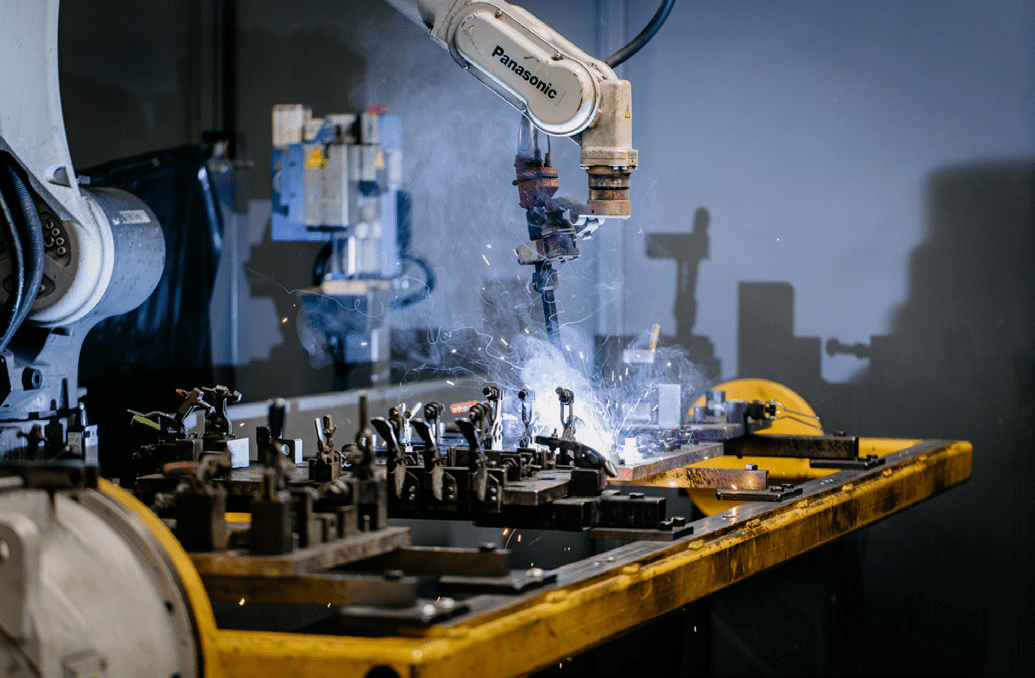

Ease of automation

MIG (Metal Inert Gas) and MAG (Metal Active Gas) is well-suited for automation and robotic welding applications. MIG/MAG welding is a type

of arc welding process that uses a continuous solid wire electrode and a shielding gas to protect the weld from atmospheric contamination.

Clean welds

MIG and MAG produces clean welds with minimal slag. In some applications, TIG welding can be performed without filler material, resulting in a

clean weld.

Precision and accuracy

Robotic welding, particularly robotic TIG, offers precise control over the welding process, resulting in high accuracy and weld repeatability. This is particularly beneficial for applications with tight tolerances.

Versatility

TIG welding can be used on a wide range of materials, including exotic metals.

No flux or filler needed

TIG welding can sometimes be performed without filler material, resul-ting in a cleaner weld.

Adaptability

Manual welding is highly adaptable and can be used in a wide range of applications, including complex and irregularly shaped components. Cost-effective for small runs. For small production runs or prototypes, manual welding may be more cost-effective than setting up and programming a robotic welding system.

Ease of setup

Manual welding setups are generally quicker and simpler compared to setting up and programming robotic welding systems.

Consistent quality

Robotic welding systems provide consistent and repeatable weld quality, reducing the variability introduced by human factors.