While medtech and complex rehab are two of our primary markets, our solutions are also used in other applications where motion systems must meet exceptionally high demands for performance and reliability.

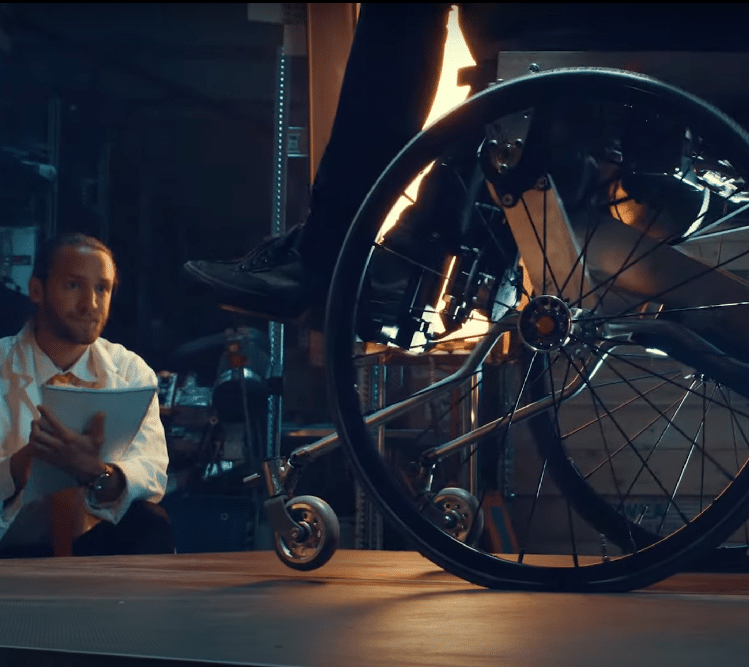

From the start, we have been passionate about developing solutions that help make people’s lives simpler and more independent. We have also been able to fulfill this ambition in close collaboration with some of the world’s leading wheelchair manufacturers. For many of them, we have become a trusted innovation partner.

Top quality, professionalism, innovation, and reliability are the cornerstones of our organization and everything we do. Technical excellence is a non-negotiable, enabling us to bring true innovation power to our customers’ development projects. When our R&D resources work closely with a customer’s R&D team, we truly push technical boundaries together. Technical challenges inspire us, as they offer the opportunity to turn them into value-creating solutions. Our teams’ ability to “think outside the box” and present alternative solutions to initial concepts, often results in breakthrough innovations and stronger market positions.

Your challenges and high ambitions make us better

The medical technology sector is experiencing rapid technological development. Fast-paced innovation is paving the way for solutions that improve healthcare efficiency and raise the quality of both treatments and rehabilitation. One important trend is the launch of new, advanced wheelchair solutions that allow people with limited mobility to live freer, better, and more active lives.

Smarter functions, more compact designs, lower weight, shorter time-to-market, and uncompromising premium quality for all components—these are some of the driving forces behind many development initiatives. These challenges also drive medtech companies to seek out strong development partners who can play an active role in R&D projects. REAC is one such partner. We are proud to have collaborated with customers on recently launched solutions that have attracted global attention.

Why did they choose REAC? Proven technology, premium quality, innovation capacity, large-scale manufacturing resources, strong R&D capabilities, and our ability to design actuators tailored to exact customer specifications have often been decisive in making REAC the innovation partner of choice. Our compliance with RESNA certification and multiple ISO standards helps medtech companies meet regulatory requirements more easily and quickly.

REAC delivers customization

One of REAC’s greatest strengths is our capability to deliver tailored solutions. Instead of forcing you to adapt your products to fit standardized components, we design actuators that integrate seamlessly into your system architecture. Our engineers will quickly produce drawings specific to each customer need. Often, we can modify existing solutions from our extensive portfolio; other times, we develop entirely new designs.

For our customers, this flexibility is unique compared to the limitations of choosing from a narrow standard assortment. Our ability to provide custom-engineered solutions, even for small production runs, is especially important in medtech, where the development and launch of new products will often begin with smaller series.

- Njord Medtech (Sweden) focuses on innovative solutions for patient handling and radiology. Their Atle 180 system enables smooth lateral transfers between hospital beds and exam tables, reducing strain and stress for caregivers, while ensuring greater comfort and dignity for patients. Our ability to meet the demanding customization requirements for actuators and control systems was a key reason for Njord to choose REAC as their innovation partner.

- SIMO GmbH (Germany) has developed the SIMO wheelchair simulator, which helps users achieve optimal seating posture before production. This prevents health issues and guarantees a perfect fit—something traditional wheelchair manufacturing often lacked. REAC was selected as a partner thanks to our willingness to deliver high-quality actuators and control systems in small volumes, combined with our ability to engineer ultra-compact customized actuators that fit SIMO’s unique design. The result was a successful project that has attracted significant interest across both the U.S. and Europe.

- A global mobility manufacturer launched an electric wheelchair with an innovative column lift. The seat can be elevated 12 inches in just over 10 seconds, and the wheelchair can be driven in the highest position, delivering an entirely new mobility experience, and allowing social interaction at eye level. REAC co-developed a customized column lift solution that met demanding requirements for power, reliability, and design.

- Mercado Medic AB (Sweden) is a well-known supplier of manual and powered medical chairs and wheelchairs. Their Real 6100 Plus features an extremely narrow chassis for maneuverability in tight spaces, and a wide seat-height adjustment range for reaching higher surfaces. Mercado’s stringent demands on functionality and quality made REAC their ideal partner for customized actuators and control systems.

R&D resources tailored to your design processes

At REAC, we take pride in the innovation capacity of our R&D teams. Their technical expertise translates into a flexible tresure trove of knowledge for our customers. These R&D resources can be tailored precisely to fit your design process—whether you need additional design competence in specific stages, or a full-scale partner in developing entirely new actuator solutions.

Our R&D engineers are proud to contribute knowledge that evolves, improves, and optimizes our customers’ ideas and design processes. When we are involved early in the process, we often identify solutions that may not be immediately visible to our customers’ internal teams. These solutions can lead to more attractive designs, higher quality, more efficient production, and reduced costs.

Early involvement also helps prevent costly ”rethink” scenarios, where late-stage redesigns are forced by component limitations, such as actuators not meeting performance requirements. By avoiding this, you will prevent significant time-to-market delays and development costs.

Through close collaboration, transparency, and integrated R&D resources, we have successfully co-created custom solutions that have led to entirely new product launches in the medtech industry. Our work follows a proven multi-step process:

- Needs analysis

Understanding customer objectives and solution requirements. Many times, there are existing actuators in our range that match perfectly. If not, small adaptations will usually suffice. Benefits for you are shorter time-to-market and cost efficiency. - Feasibility & application study

Our engineers analyze available space, load requirements, stroke length, and speed. - Concept development

We propose one or more solution concepts. - Design proposal

Our R&D team creates detailed designs with full technical specifications. - Manufacturing

Solutions are manufactured at our advanced production facility in Poland.

Our commitment does not end when actuators and seating modules leave the factory. Given the fast pace of innovation in the medtech sector, we continuously monitor evolving needs, and ensure upgrades that keep motion systems future-ready. As a true innovation partner, we help our customers not only bring new solutions to market, but also continue to innovate on existing innovations.

Meet the talent behind the technology! Over the coming weeks, we’ll be rolling out the red carpet for four of our coworkers—the folks who put the “wow” in medtech innovation, and probably consume more coffee than is scientifically necessary. We’ll be sharing their stories, quirks, and the nerdy passion that powers our R&D adventures. Don’t miss out on meeting some of the REAC stars who transform your wild ideas into reality!